Fuel control is one of the strengths of Wialon. The system has long been able to calculate the actual and expected fuel consumption for groups and individual units, as well as track fuel fillings and drains in real time or for the past period. But Wialon has another important tool for fuel control, which may not be known to everyone, although it opens up a unique opportunity for accounting dispenses by refuelling trucks. We are talking about the Fuel Traffic table, and this is what is considered in this article.

Table features

The Fuel Traffic table is unusual for several reasons. In fact, it combines three tables: Fuel Fillings and Battery Charges, Fuel Drains, and Counter Sensors. Despite the fact that it is not available for unit groups, when you run a report on a refuelling truck it can display data for other units that receive fuel (namely, customer units).

This table can be used in different ways:

- For a refuelling truck to display fuel dispensing to customer units.

For any unit to display all its fuel fillings and drains in one list.

- Combining the first and second methods to see both fuel fillings and dispensing of a refuelling truck.

Only the first method is considered further in the article since it requires more non-standard settings comparing with the second one.

Necessary sensors

Unit type | Sensor type | Opportunities |

Refuelling truck | Fuel level sensor (FLS) | Allows displaying fuel dispensing (as drains) and refuelling (filling the tank with fuel). |

Refuelling truck | Allows displaying the amount of fuel dispensed through the fuel filling gun with flow meter. The use of a counter gives a more accurate result compared to the FLS. | |

Customer unit | Allows displaying the volume of filling when receiving fuel from the refuelling truck. | |

Refuelling truck | To display a driver's name, a card reader must be installed on the refuelling truck. It is assumed that the driver of the customer unit swipes their card to the refuelling truck's card reader to start dispensing, and for this time they are assigned to the refuelling truck. After the dispensing is completed, the driver must be separated from the unit. |

The logic of the table

Let's take a step-by-step look at the operation logic of the Fuel Traffic table for the case when it is executed for a refuelling truck.

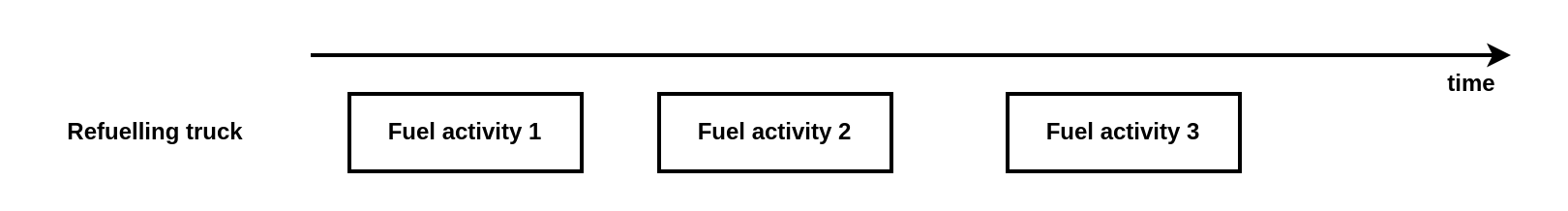

When running a report for the selected interval, the table searches the refuelling truck for Fillingies of various types: fuel fillings, drains, or counter performance. The search is carried out in the same way as in the tables of the same name — Fuel Fillings and Battery Charges, Fuel Drains, and Counter Sensors. It is possible to filter the types of fuel actives to be displayed in the table settings. The logic of working with all three types of activities is the same. For simplicity, let's assume that only fuel dispensing is considered in the example.

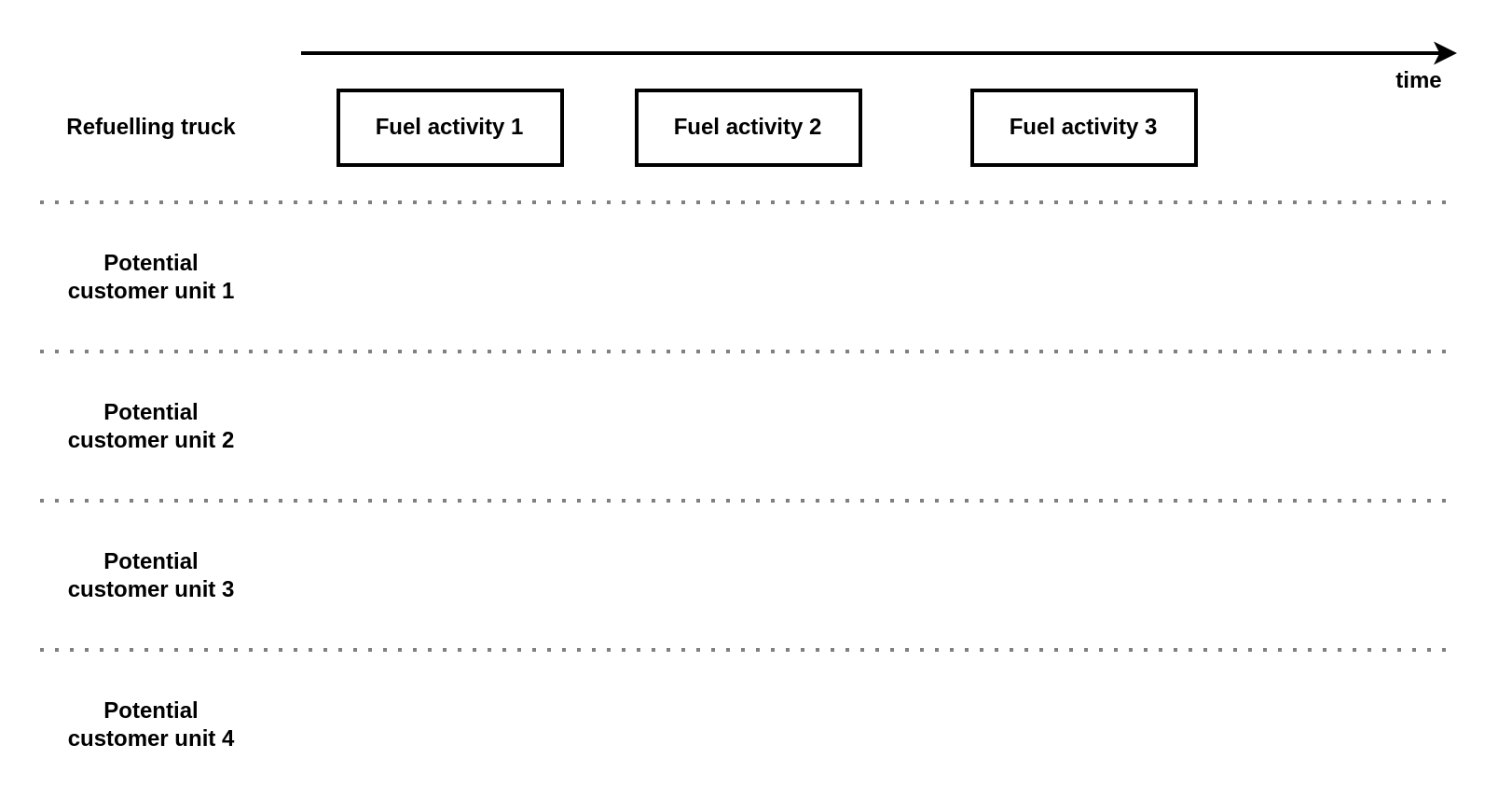

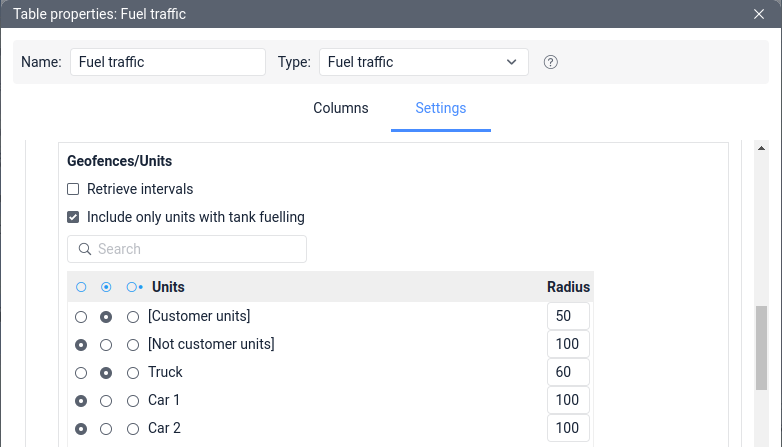

Next, the system looks for potential customers, that is, other units that were close to the refuelling truck during its fuel activities. The distance to these units is compared with the radius of approximation, which is specified in the settings of the Fuel Traffic table. Let's assume that several such units are found.

The next step, the system starts searching for fuel fillings for the units found nearby. The search is carried out in the same way as in the Fuel Fillings and Battery Charges table.

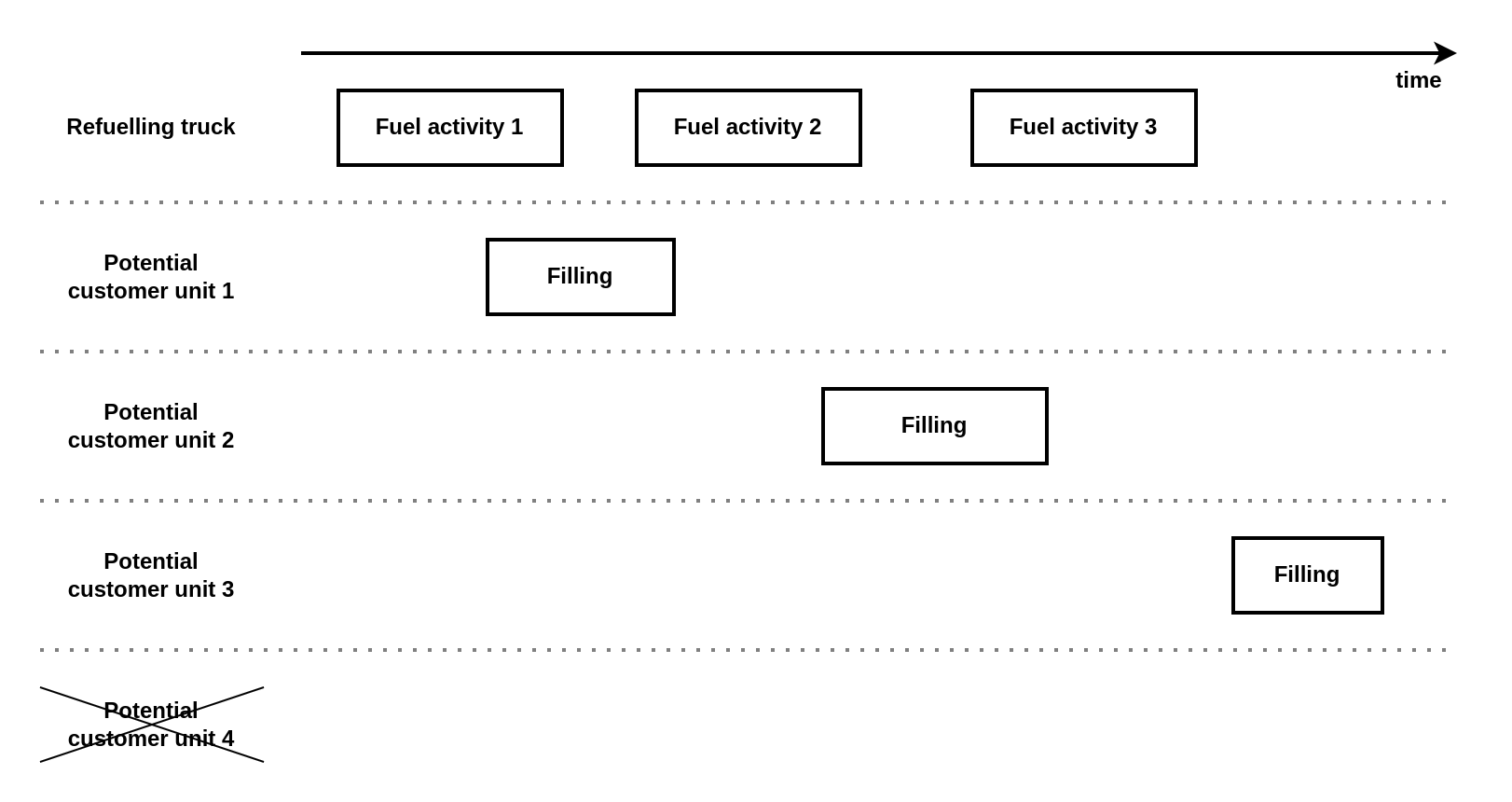

If the Include only units with tank fuelling option is enabled in the table settings, then units without fillings will be excluded from further analysis and display. And if this option is disabled, then the report will include even those units that were simply near the refuelling truck at the time of fuel activities, but did not have fillings. Let’s suppose that the option Include only units with tank fuelling is enabled in our example.

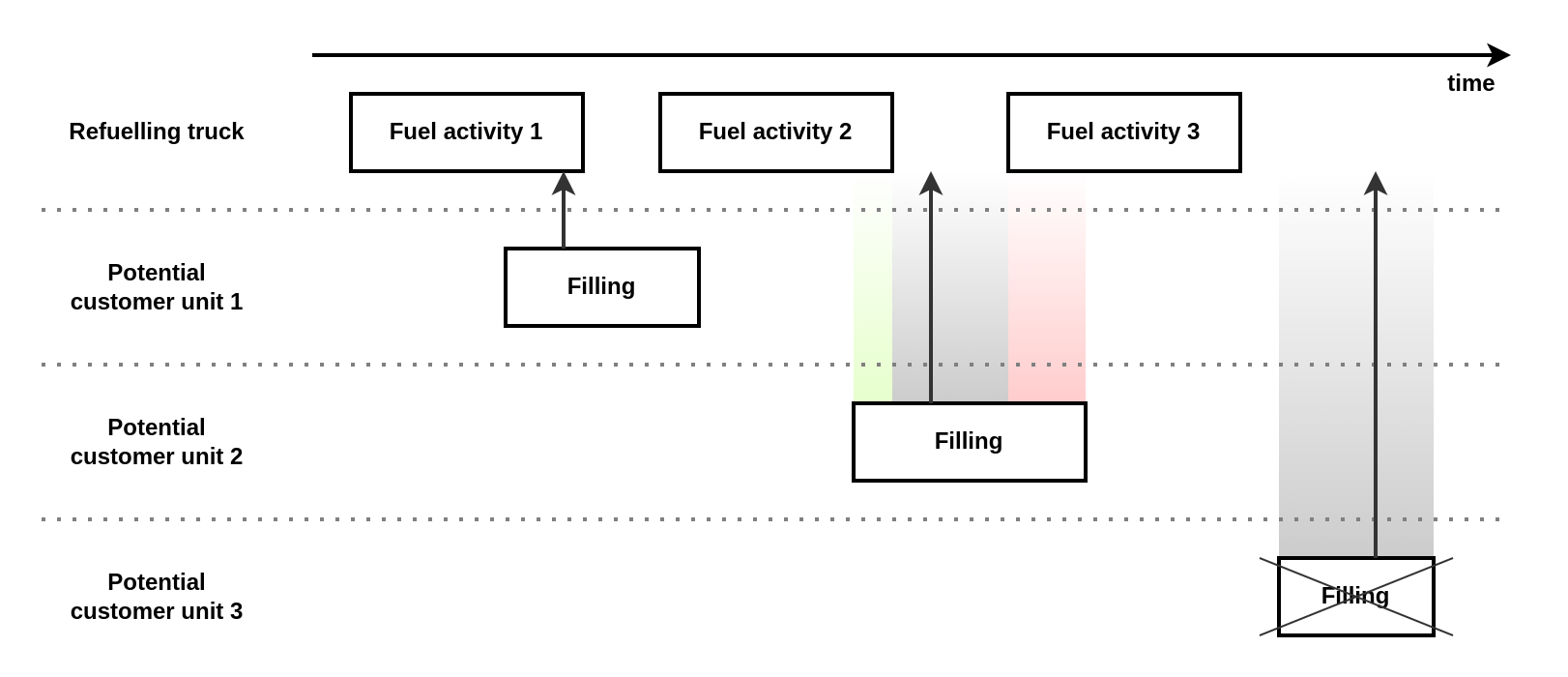

At the moment, the system has already calculated the refuelling truck activity intervals and the filling intervals of customer units. Now we need to adjoin them.

If the filling time of a potential customer falls within the fuel activity, then the filling and fuel activity are considered to be adjacent. If such a hit did not happen, then the algorithm looks for intersections of the filling interval with the interval of fuel activity. If there are several such intersections, then the filling will be adjacent to the first fuel activity in terms of time. If the filling interval does not intersects with any fuel activity, then the customer unit and its filling will not be displayed in the report.

In the example shown in the pictures, we get:

- The fuel activity 1 row will display the fuel filling of the potential customer 1.

In this case, the filling time (maximum fuel level difference) of the customer unit falls within the dispensing interval. - The fuel activity 2 row will display the fuel filling of the potential customer 2.

The time of this filling does not fall within the dispensing intervals, however, the fuel filling has intersections with several dispensing activities and will be related to the very first one. - No fuel fillings will be displayed in the fuel activity 3 row.

The filling interval of the potential customer 3 does not overlap with any fuel dispensing. - The potential customer 4 will not be displayed in the report.

No fuel fillings were detected for it, and according to the condition of the example, the option Include only units with tank fuelling is enabled in the table settings.

The names of the customer units will be displayed in the Geofences/Units column, the Filled column will contain the volume of the customer unit fuel fillings, and the Deviation column will contain the difference between fuel filling and dispensing.

Example of settings for fuel dispensing control

Let's consider an example of setting up the Fuel Traffic table to control dispensing by a refuelling truck. By default, this table displays all types of fuel activities, so you must first hide the unnecessary ones, and then configure the remaining ones.

Please remember that the settings may vary depending on the equipment used and its accuracy, as well as the needs of the client. However, most of the steps in the instructions below are still the same for all users.

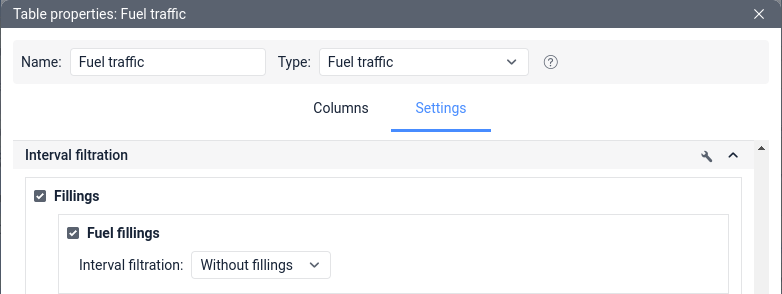

- To hide refuelling truck fillings, open the Fillings block in the interval filtration, enable the Fuel fillings filter in it, and select the option Without fillings in the drop-down menu.

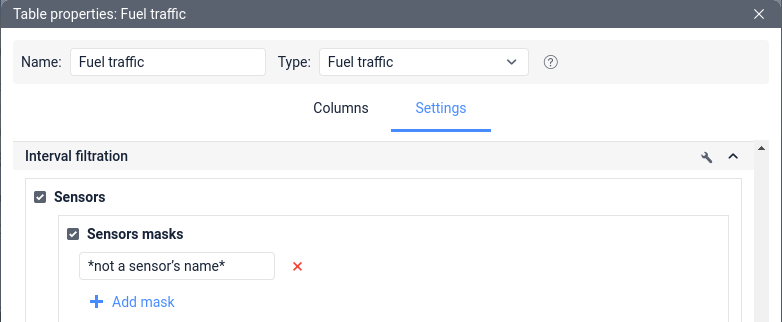

- If the fuel dispenser does not have a fuel filling gun with flow meter installed, while other counter sensors are created for the unit, they may affect the displayed result.

To hide the readings of these counters, open the Sensors block in the interval filtration, enable the Sensor masks filter in it, and specify a name that does not match the names of the counters. - If a refuelling truck is equipped with a fuel filling gun with flow meter, it is recommended to work with its data and not with fuel drains detected by the FLS.

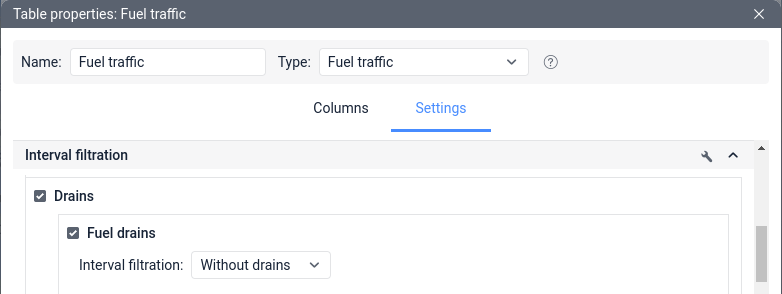

To hide fuel drains from the fuel dispenser, open the Drains block in the interval filtration, enable the Fuel drains filter in it, and select the Without drains option in the drop-down menu. Depending on the previous steps, at this stage the report will only display the acts of fuel dispensing recorded by the FLS or by the counter.

In both cases, to display customer units and their fillings, it is necessary to mark the necessary units or unit groups in the Geofences/Units filter and specify the radius of approximation. This filter is repeated in each of the blocks (Fillings, Drains, Sensors), so you need to configure it in the block that you plan to use.

It is also recommended to enable the Include only units with tank fuelling option to hide the units that were just nearby but did not have fillings from the report results.

Solving possible issues

Below we consider common issues that arise when working with the Fuel Traffic table and methods for solving them.

Dispensing or filling volumes do not converge

If the volumes in the Fuel Traffic table do not converge, then you need to perform the same actions as if the incorrect results were in the Fuel Fillings and Battery Charges, Fuel Drains, and Counter Sensors tables. You can verify:

- The availability of sensor parameters in messages from the truck and the customer unit.

- Calibration of the refuelling truck and customer unit tanks.

- Refuelling truck counter coefficient (if used).

- Additional settings for the fuel sensors of the refuelling truck and the customer unit.

You might find our other fuel-related articles in the Miscellaneous section helpful.

The customer unit is not displayed or is displayed incorrectly

This issue may be related to the inaccuracy in determining the location of the refuelling truck or customer units.

You can check location-related tracker configurations or increase the radius of approximation in the settings of the Fuel Traffic table.

Based on the logic of the table discussed above the issue may be related to how and when a dispensing of a refuelling truck or a filling of a customer unit are detected. Therefore, you can follow the recommendations from the previous paragraph about the inconsistency of the volumes of dispensing or filling.

The dispensing is divided into several parts

If the dispensing is determined by the counter, then you can set the merge intervals condition in the Sensors section in the settings of the Fuel Traffic table. For example, if you set the Timeout less than 30 seconds, then the counter intervals with less than 30 seconds in between will be merged.

If the dispensing is determined by the FLS, then you can increase the Timeout to separate consecutive drains in the FLS properties.

The acts of dispensing are not split

A possible cause of this issue is the low frequency of sending data, due to which it is not possible to receive a sufficient number of messages between the acts of dispensing from the tracker.

You can also apply the recommendations from the previous paragraph, but vice versa: reduce the Timeout less then in the merge intervals condition or reduce the Timeout to separate consecutive drains in the FLS properties.

Lots of little extra acts of dispensing

It is possible that the fuel filling gun through which the fuel is dispensed is leaking, that is, fuel is dripping through it even when closed.

It would be most correct to repair the equipment, however, from the Wialon side, you can set the minimum Counter sensor value range in the Fuel Traffic table settings which will allow you to ignore small dispensing.

Drivers are not displayed correctly

Drivers may not appear in the report, or the same driver may appear in all rows.

There is no single instruction for fixing such a issue, since the process of working with drivers depends on the equipment used.

Try to study the logic of automatic assignment and separation of drivers. You may need to verify:

- Availability of driver assignment sensor parameters in the messages from the refuelling truck.

- Driver assignment sensor settings including the separation code.

- Properties of drivers, namely, their codes.

- Settings of the automatic assignment list.